Inspection & (periodic) Maintenance

ETR provides all kinds of inspection, services and maintenance.

When inspecting electrical systems, different standards, regulations and supplementary provisions apply. Which one applies, depends on the use of the system, year of first installation, changes made, the system, the power supply, and the main security. Upon inspection, the state of maintenance of the installation and connected equipment is examined. Inspections of existing electrical/technical installations and connected equipment are inspected in accordance with the European guideline EN 50110 and the additional Dutch standard NEN 3140. The stated issues in the report are arranged to risk danger. In a maintenance agreement we can ensure that you are guaranteed legally and insurance technically against the ‘small print’.

Inspection of:

▪ Electrical installations

▪ Checking electrical tools

▪ Thermography / Infrared

▪ Control/Checking technical/electrical drawings

▪ Measurements

Inspection of the electrical installation takes place through visual inspection, measurement and testing. In addition, the system may be inspected by means of a thermographic inspection.

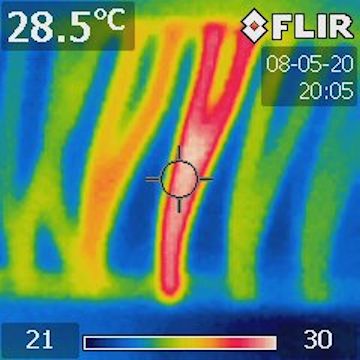

Thermographic inspection

No visual inspection takes place. Using an infrared camera, electrical cabinets are scanned on thermal cycling and elevated temperatures. These heat differences can mutually occur between the components at the/a(n):

▪ Main switch

▪ Internal wiring

▪ Rail Compounds/connections

▪ Switches and disconnectors

▪ Phase load(s)

▪ Manufacturing errors

▪ Loose or poor contacts (*)

(*) A loose contact gives a contact resistance resulting in heat generation, which is made visible by infra-red -measurements.

Benefits

The benefits include i.a.:

– Installations are tested under operating conditions, the thermal control/ inspection is

contactless.

– Flammability situations are made visible at an early stage.

Please contact us for more information.